Inverter AC vs Non Inverter AC

Inverter Air Conditioner:

An inverter air conditioner has a variable speed compressor rather than a one with fixed speed. Through this technology, the compressor runs all the time and does not start and stop frequently. It controls the temperature by slowing down or speeding up as required. Inverter technology is considered to be more energy efficient. The compressor life may also be a bit longer as the compressor does not have to start and stop continuously Inverter air conditioners are generally quieter in their operations. This is because they don’t frequently turn on and off based on the room temperature. Inverter air conditioners are usually more expensive than the regular non inverter type but may make a good buying decision as they last longer and are more energy efficient. Inverter technology is the latest technology for air conditioners. They use inverters to convert AC to DC and then regulate the compressor speed. Such air conditioners have a mechanism to check the ambient temperature in the room and then transmit this information back to the compressor controller, which in turn changes the compressor speed (instead of stopping and starting).

Non-Inverter Air Conditioner:

Non inverter AC provides a fix heating or cooling by a fixed power with the compressor running at a fixed speed. The compressor has to start and stop when required. On the other hand inverter air conditioners have a controllable compressor that provides the exact amount of heating and cooling as needed. Non inverter or fixed speed air conditioning delivers a fixed amount of power via a fixed speed. This means the compressor has to stop and start to maintain the desired room temperature. Inverter air conditioning systems varies the speed of the compressors thereby delivering precise cooling or heating power as required.

Inverter VS Non Inverter: Have you ever wondered what the difference is between inverter and non-inverter AC? Take a look at the top 5 advantages of inverters that make them better than non-inverters.

Eco friendly

The biggest difference between inverter and non-inverter AC is the fact that the motor of the inverter compressor has a variable speed. The speed of the non-invertor compressor is fixed. This means that it operates either at full or minimum speed. A censor in the invertor adjusts the power according to the temperature in the room, lowering the electrical consumption and saving energy.

Saving money

Due to the sophisticated operational method of the invertor, its compressor does not work at its full capacity all the time. When the speed is lower, the needed energy is lower too and you pay less money for electricity.

More quiter sound

As the compressor motor of the inverter air conditioner does not turn on and off all the time, but keeps working at low power, the operation is more quite.

Longer life

The technology of the inverters not only makes cooling and heating more efficient, but it also makes the AC’s life longer.

Faster Cooling/Heating

Last but not least, the inverter AC is able to cool or heat your room faster than the non-inverter. This is due to the fact that in the beginning of the process, the inverter uses more power than the non-inverter and diminishes the power when it gets close to the desired temperature.

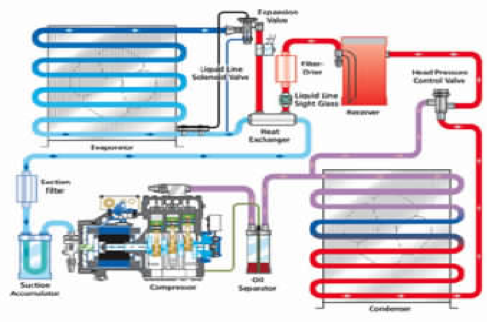

Commercial Refrigeration Cycle

Here is an example of a Commercial Refrigeration System. Beginning at the compressor the refrigerant is compressed into a high pressure high temperature vapour. The refrigerant travels to the oil separator where the oil is separated from the refrigerant and is transported back to the compressor to help keep the compressor cool and running smoothly. The refrigerant travels to the condenser where a decrease in temperature occurs due to the fan blowing over the condenser and the vapour condenses to a liquid. The refrigerant is now a high pressure high temperature liquid. The refrigerant travels through the Head Pressure Control Valve which performs the function of limiting flow of refrigerant from the condenser and at the same time regulate the flow of hot vapour in the condenser to the receiver during low ambient temperature conditions, so as to keep the refrigerant in the liquid line at the ideal pressure. The liquid refrigerant moves to the liquid receiver and accumulates there. The receiver ensures that only liquid is taken to the thermostatic expansion valve (TXV). On the way to the TXV the refrigerant passes through the liquid line filter drier to be cleaned, through the liquid line sight glass to see if there is enough refrigerant going to the TXV and through the heat exchanger to slightly lower the temperature of the refrigerant using the cold temperature of the low pressure suction pipe after the evaporator and prepare the refrigerant temperature for change of state at the TXV. When required there is a liquid line solenoid valve that will close when necessary and stop refrigerant flow to the TXV. On arrival to the TXV the liquid refrigerant under goes a decrease in pressure as it passes through the valve. The TXV also regulates the amount of refrigerant that goes to the evaporator using the feeler bulb on the end of the evaporator coil. As the liquid refrigerant passes through the evaporator the refrigerant evaporates and absorbs heat. The fan blowing over the evaporator ensures there is minimum ice build-up on the evaporator coil and to circulate the cold air throughout the room. The refrigerant is now a low pressure and low temperature vapour. The refrigerant vapour exits the evaporator and enters the heat exchanger where the vapour is heated slightly using the warm temperature of the liquid line refrigerant pipe which prepares any liquid refrigerant for evaporation in suction accumulator. The suction line filter drier cleans and purifies the refrigerant before it arrives at the compressor. The suction accumulator evaporates any liquid refrigerant leftover and ensures only refrigerant vapour travels to the compressor.

Maintaining Your Air Conditioner

An Air Conditioner should be serviced regularly every 4 to 6 months due to the following reasons:

An air conditioner's filters, coils, and fins require regular maintenance for the unit to function effectively and efficiently throughout its years of service. Neglecting necessary maintenance causes a steady decline in air conditioning performance while energy use steadily increases. Air Conditioner Filters The most important maintenance task that will ensure the efficiency of your air conditioner is to routinely replace or clean its filters. Clogged, dirty filters block normal airflow and reduce a system's efficiency significantly. With normal airflow obstructed, air that bypasses the filter may carry dirt directly into the evaporator coil and impair the coil's heat-absorbing capacity. Replacing a dirty, clogged filter with a clean one can lower your air conditioner's energy consumption by 5% to 15%. For central air conditioners, filters are generally located somewhere along the return duct's length. Common filter locations are in walls, ceilings, furnaces, or in the air conditioner itself. Room air conditioners have a filter mounted in the grill that faces into the room. Some types of filters are reusable; others must be replaced. They are available in a variety of types and efficiencies. Clean or replace your air conditioning system's filter or filters every month or two during the cooling season. Filters may need more frequent attention if the air conditioner is in constant use, is subjected to dusty conditions, or you have fur-bearing pets in the house.

Air Conditioner Coils The air conditioner's evaporator coil and condenser coil collect dirt over their months and years of service. A clean filter prevents the evaporator coil from soiling quickly. In time, however, the evaporator coil will still collect dirt. This dirt reduces airflow and insulates the coil, reducing its ability to absorb heat. To avoid this problem, check your evaporator coil every year and clean it as necessary. Outdoor condenser coils can also become very dirty if the outdoor environment is dusty or if there is foliage nearby. You can easily see the condenser coil and notice if dirt is collecting on its fins. You should minimize dirt and debris near the condenser unit. Your dryer vents, falling leaves, and lawn mower are all potential sources of dirt and debris. Cleaning the area around the coil, removing any debris, and trimming foliage back at least 2 feet (0.6 meters) allow for adequate airflow around the condenser. Coil Fins The aluminium fins on evaporator and condenser coils are easily bent and can block airflow through the coil. Air conditioning wholesalers sell a tool called a "fin comb" that will comb these fins back into nearly original condition. Condensate Drains Occasionally pass a stiff wire through the unit's drain channels. Clogged drain channels prevent a unit from reducing humidity, and the resulting excess moisture may discolour walls or carpet.

Window Seals for Room Air Conditioners At the start of each cooling season, inspect the seal between the air conditioner and the window frame to ensure it makes contact with the unit's metal case. Moisture can damage this seal, allowing cool air to escape from your house. Preparing for the Winter In the winter, either cover your room air conditioner or remove and store it. Covering the outdoor unit of a central air conditioner will protect the unit from winter weather and debris. Hiring a Professional When your air conditioner needs more than regular maintenance, hire a professional service technician. A well-trained technician will find and fix problems in your air conditioning system. The technician should: • Check for correct amount of refrigerant • Test for refrigerant leaks using a leak detector • Capture any refrigerant that must be evacuated from the system, instead of illegally releasing it to the atmosphere • Check for and seal duct leakage in central systems • Measure airflow through the evaporator coil • Verify the correct electric control sequence and make sure that the heating system and cooling system cannot operate simultaneously • Inspect electric terminals, clean and tighten connections, and apply a non-conductive coating if necessary • Oil motors and check belts for tightness and wear • Check the accuracy of the thermostat.